Steel rolling

High requirements

All our machines meet the highest requirements on rolling of different types of profiles. We employ a registered production method, which is your guarantee for the highest quality.

We offer steel rolling within the following areas:

We offer custom-made solutions

Thanks to our versatile machinery, we can handle any project – from a single profile to thousands of profiles, large as small.

All projects are customised to meet our customers’ wishes and needs so that the materials will match your production completely.

We also roll

Of course, we would be pleased to undertake the final adjustments once the profiles have been rolled. All you have to do is tell us how we can help you best. Moreover, we also offer further processing of the profiles such as welding, drilling, etc. so that the completed work pieces can be applied in your production immediately

For further information on our services, please feel free to contact us. We would be pleased to make you a non-binding offer.

Tube bending for your project

Tube bending is a natural extension to our rolling department. Typically, tube bending is performed on a CNC-controlled tube bending machine where we bend:

- Round tubes

- Square hollow profiles

- Flat oval tubes

- Special profiles

We offer a wide selection of bending dies, and if needed, we can produce new dies for your personal project very quickly. We would be pleased to be part of your development process where we offer extensive experience and knowledge of tube bending. We have experience in tube bending from several standard and special profiles in the following metals:

- Stainless steel

- Black steel l

- Aluminium

- Brass

- Copper

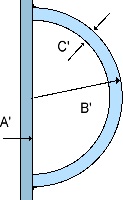

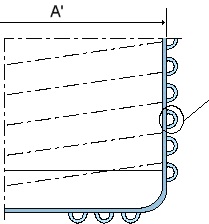

Rolling of half tube spirals

The spirals can be made in all bendable steel qualities and metals, and in several dimensions. Half tubes are applied for heating/cooling spirals on tanks etc. that are used in oil, chemical and food industries. Unlike the traditional heating jacket, a half tube spiral can withstand a higher pressure, and thus, the utilisation is increased.

| DN | B' = UDV. Ø | C' = PL. T. | Made in |

|---|---|---|---|

| 32 | 42,9 | 2-3 | Steel Stainless Aluminium Brass Cobber |

| 40 | 48,3 | 2-3 | |

| 50 | 60,3 | 2,5-3 | |

| 65 | 76,1 | 2,5-3 | |

| 80 | 88,9 | 2,5-3 |

Rolling of truncated cones

Besides sheets, we also offer rolling of truncated cones, T-fittings, and façade plates. We have developed a special rolling technology, securing a nice surface of the façade plates. Thus, you can always be sure that we handle your plates with the utmost care so that the final façade plate turns out the way it should – to be of the highest quality.

Plate rolling

Gustav Østergaard started profile and plate rolling more than 50 years ago. Thus, our company has achieved extensive experience in plate rolling.Today, we roll all types of metals; typically stainless steel, black steel, and aluminium. The rolling is conducted on a CNC-controlled plate roller featuring a width capacity of 3,000 mm.For rolling of sheets, we have our own in-house certified welders. Thus, we also perform longitudinal welds, circular welds, and other types of welding.

Rolling of special profiles

Our goal is to be best in business when it comes to rolling of special profiles. For many years, we have been focusing on technically difficult profiles. At the time of writing, we can conclude that we have been able to roll all special profiles. Over the years, we have created rollers for a multitude of special profiles. Therefore, Gustav Østergaards Maskinfabrik A/S is always ready to help and advise you when your special project involves the design of special rollers that need to be adjusted to the specific profile. Gustav Østergaards Maskinfabrik A/S would be pleased to participate in an active development process so that we can ensure the rollability of the profile, while retaining its other properties - something we know a great deal about.